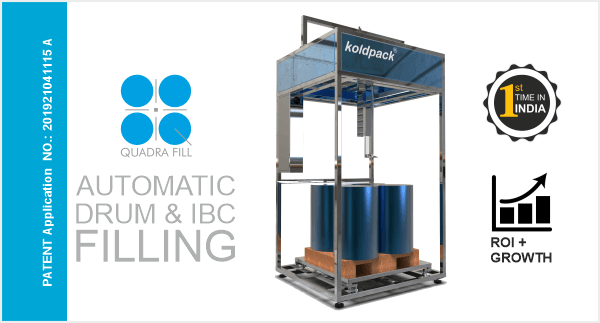

We all know that world is heading towards more and more automation in all industries globally. There can be hundreds of different reasons for Automation in various industries, but when it comes to Automatic Drum Filling Machines, it has its own special advantages.

Drums are used for Bulk filling and thus are for Bulk producers/manufacturers of various types of liquids starting from Food, Chemicals, Petrochemicals, Lubricants, Pharma, etc. Below are the key reasons why once should go for Automation in Drum Filling:

Less Manpower

Automation is meant to reduce human interventions in industrial operations. Our Fully Automatic QUADRA FILL operates with one click to fill in all drums & thus what 3 people operation is required normally is reduced to a single skilled operator. That NOT only saves money over manpower but also reduces HR pressure in managing more people. Lesser manpower in industry helps to ease industry labor compliances with local regulatory authorities. We all know that reducing one person in a company means not just saving one person’s salary but saving 1.5 times of salary due to other overheads in managing manpower. There are larger examples today worldwide wherein those who have used Industry 4.0 standards, which is heading towards integrated process management using IOT, they have reduced manpower from 100 people to just 2 person on industrial floor operations. Biggest examples are set by Cadbury, Ford, Amazon, etc.

Speedy & Accurate Operations

We humans are known to commit mistakes when we are given monotonous activities & machines DO NOT. We have tendencies to take breaks at intervals & machines DO NOT. Our software which is especially developed in QUADRA FILL helps define recipes for each product, filling tolerances and many more… thus giving you accuracy in filling over and above speed. Machines are meant for continuous operations & our Fully Automatic Drum Filling Machine QUADRA FILL is designed to work for days. We very well know saving a few milliliters of product per drum, leads to saving of huge revenue losses yearly.

Integrated Software with detailed reporting

Manually operated machines are not supplied with any type of computer, but just with simple HMI or at the most HMI with PLC. On the other hand, QUADRA FILL is fully equipped with ACADA (SCADA) software giving edge over filling operation cycles. ACADA is 3rd generation SCADA, integrated on one hand tightly with PLC & on the other with Camera operations to intelligently detect drum bungs/holes. ACADA software has extended User Rights management facility for Admin, Manager, Supervisor & Operators. Batch Wise & Filling cycle wise historical reports can be generated. User Wise / Shift wise reports can be generated for understanding operators efficiencies. ACADA captures operational data from all connected electronics in such a way, that statistical reports can be generated which can help you in developing & forecasting operational SOP’s of future. ACADA also helps you to forecast machine maintenance cycles, thus making it fully integrated along with MIS report generation.

Avoids Contamination

CONTAMINATION issues are given utmost importance in food industry wherein especially when edible food products are filled in drums. More of human intervention in industrial operations leads to higher chances of contamination. COVID-19 pandemic global situation has taught a lot to world about contamination. QUADRA FILL automated operations helps contact less drum filling reducing chances of contamination to almost null. There are various operations like uncorking, filling, corking & sealing which when manually done by humans can cause contaminations to edible products.

Hazardous Environment Operations with ATEX compliances

There are liquid products which are highly evaporative as well as inflammable in nature which creates situation of explosiveness in an industrial environment. The Dangerous Substances and Explosive Atmospheres Regulations 2002 (DSEAR) place duties on employers to eliminate or control the risks from explosive atmospheres in the workplace. QUADRA FILL is having it’s variant which complies to such ATEX regulations. ATEX is the name commonly given to the two European Directives for controlling explosive atmospheres. Directive 99/92/EC (also known as ‘ATEX 137’ or the ‘ATEX Workplace Directive’) on minimum requirements for improving the health and safety protection of workers potentially at risk from explosive atmospheres. Directive 94/9/EC (also known as ‘ATEX 95’ or ‘the ATEX Equipment Directive’) on the approximation of the laws of Members States concerning equipment and protective systems intended for use in potentially explosive atmospheres.

We have tried to achieve the highest level of Automation on one hand and following industrial guidelines / regulations on the other hand in QUADRA FILL to make if Fully Automatic. We shall keep trying to deliver industry requirements in Drum Filling Machine Manufacturing from time to time in coming times. We believe in continuous learning from the industry & keep implementing upcoming technologies. Our goal is to deliver something which in-turn gives us appreciation. Thanks to all readers & do visit www.DrumFillingMachine.com

- FIVE (5) REASONS FOR AUTOMATIC DRUM FILLING MACHINE - October 31, 2020